Rudzi Rutsva Runokurumidza Mold Shandura EPS Shape Molding Machine

Technical Data

| Item | Unit | Type/Technical Data | ||

| PSZ1214EP | PSZ1218EP | |||

| Mold Dimension | mm | 1500*1300 | 1950*1300 | |

| Max.Chigadzirwa Dimension | mm | 1400*1200*330 | 1800*1200*330 | |

| Minimum Mold Kukora | mm | 220 | 220 | |

| Stroke | mm | 210-1450 | 210-1450 | |

| Mounting Interface | Raw material | / | DN40 | DN40 |

| Steam | / | DN100 | DN100 | |

| Air compressed | / | DN65 | DN65 | |

| Mvura inotonhorera | / | DN80 | DN80 | |

| Drainage | / | DN150 | DN150 | |

| Ventilation | / | DN80 | DN80 | |

| Kushandiswa | Steam | Kg/kutenderera | 6/13 | 10/15 |

| Air compressed | m3/kutenderera | 1.3 | 1.5 | |

| Mvura inotonhorera | Kg/kutenderera | 60-100 | 150-180 | |

| Yakabatanidzwa mutoro | Hydralic mota | Kw | 7.5 | 7.5 |

| Pombi yevacuum | Kw | 5.5 | 7.5 | |

| Appr.machine uremu | Kg | 5700 | 7500 | |

| Zvose chiyero | mm | 4600×2140 ×3100 | 5000×2450 ×3500 | |

Munda Wekushandisa

EPS zvigadzirwa zvakashandiswa zvakanyanya muriwo nehove bhokisi, emagetsi zvikamu pasuru, madziro uye denga indulation, kushongedza imba uye nezvimwe.

Products

EPS Shape Molding Machine

1.Solid simbi yekuvaka inogadziriswa nepamusoro tembiricha annealing, kupisa kurapwa, pamusoro de-rusted nejecha uye yakapfapfaidza nependi inoparadza.

2.Control system inotora Japan PLC uye Chirungu chekubata chidzitiro chekushanda nyore uye kubudisa zvizere.

3.High quality uye yakagadzikana michina zvikamu, seGermany Burkert angle-seat valves.

4.Energy kuchengetedza neyakagadzirwa zvakanaka saizi yemuchina, mitsetse yepombi kuti uone kukurumidza kwemhepo yekumanikidza kuwedzera uye kuderera.

5.High flow hydraulic drive ine double hydraulic cylinder, iyo inoita kuti muchina ushande zvakatsiga uye uchivhara zvakasimba.

6.Muchina unogona kuve wakagadzirirwa kuvaka-in vacuum system, uye zvakare kune mukana wepakati vacuum system.

7.Double yekudyisa kamuri yekudya nekukurumidza kupfupisa nguva yekutenderera.

8.Balance vharafu yekudzora mhepo yakagadzikana.

9.Yakawedzerwa zinc yakavharwa makumbo emuchina inosarudzika kune mutengi wekuisa muchina pane yakakosha pasi.

10.Machine makumbo uye chikuva ndeyekusarudza.

MABASA MAKURU EMUCHINA UYU

Kuti ugare nechigadzirwa chakakura chakasiyana, muchina uyu wejekiseni une huwandu hwakakura hwendiro yekuumbwa, iyo min, dimension yakatenderedza 600 × 800 mm uye iyo max.Dimension inosvika 1200 × 1400 mm.Muchina uyu wakashongedzerwa nenhanho mbiri hydraulic system, compressed feeding system, uye yepakati simba sisitimu, yekuzorodza damper, kubata-kudzvanya tangi remvura, condensation system, komputa-inodzorwa system, digital process control system uye steam room.

CHINHU CHEMACHINERY

Iyi sisitimu haidi chero lubricant.Iyo hydraulic cylinder inoiswa mumativi maviri edoom ine kunyange mold clamping force.Iyo dome isina tsvina inogona kubata kupisa.Iyo mold kuvhurika uye kuvharika kwe mold inotungamirwa nekombuta system iyo inogona kuve nechokwadi chekudya chakanyanya kunaka.Iyo mold ejection motion inodzorwa neiyo ejection system kuti ipe yakanakisa mhando yechigadzirwa chakanyanya panguva yekuburitsa.

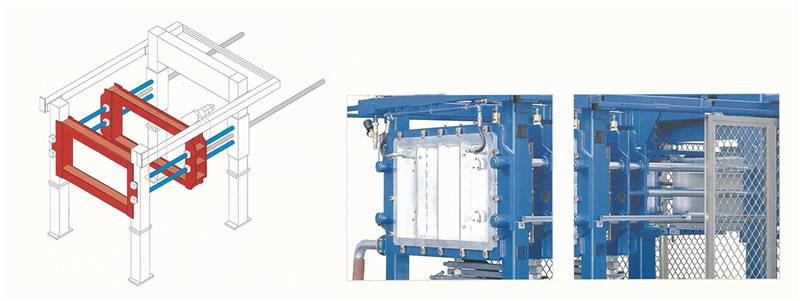

KURONGWA KWEMUCHINA UYU

Muchina uyu wakagadzirwa senzvimbo yakavhurika ine mativi matatu.Iyi yakavhurika-nzvimbo dhizaini inosimbisa iyo mold yekuchinja maitiro uye vashandisi vanogona kushandura mold kubva kumberi, kumashure uye maviri mativi emuchina uyu.Zvakare, muchina uyu unogona kuiswa zvakananga pasi pasina kuseta chero chikuva.Kuti uchengetedze kuchengetedzeka kwevashandisi, muchina uyu wakashongedzerwa negonhi rekuchengetedza uye kuchengetedza system.

MOLD SYSTEM

Iyi mold inogadzirwa mumatatu-chidimbu plate fomati.Rakawanda simba rinogona kuchengetwa pasina kuparadzwa uye saka, iyo mold plate inogona kushandiswa zvakanyanya.Mapini emutungamiri uye pfuti yekupfapfaidza akaiswa mukati me mold inofamba mahwendefa kuti ave nechokwadi chekuchengetedzwa kwekushanda.Kuti uderedze nguva yezvidhori, iyi sisitimu inopa nekukurumidza mold kuisirwa uye shanduko system.

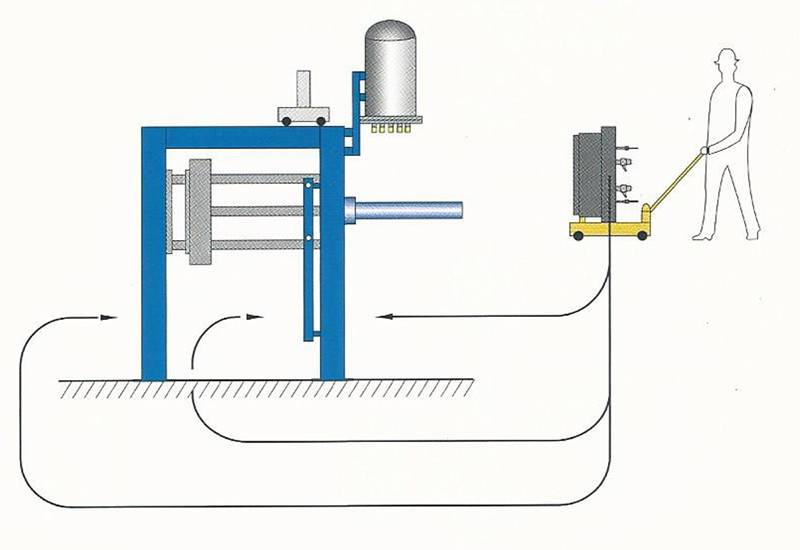

HYDRAULIC SYSTEM

Maviri-nhanho hydraulic system inopa maviri kumhanya (inokurumidza uye inononoka) sarudzo dzekuvhara mold uye mold-kuvhura.Uyewo, nguva yekugadzirisa inoderedzwa.

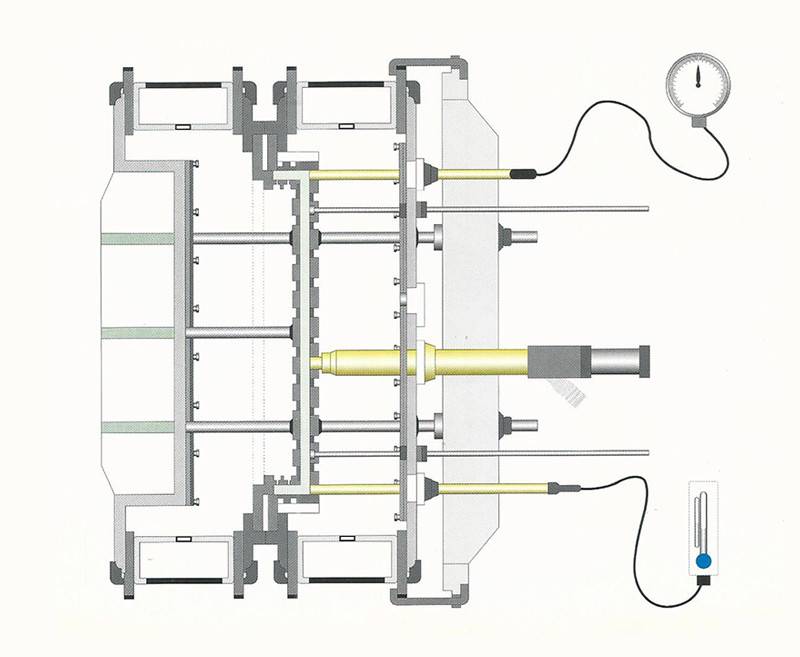

CENTRAL ENERGY SYSTEM

Muchina uyu une seti imwe yakazara yepakati simba system inogadzirwa nekambani yedu Yese mhepo nemhepo inodiwa panguva yejekiseni inodzorwa nepakati simba system valve.Iyi sisitimu ichapa kunyangwe kupinza kwemhepo uye inogona kugadziriswa nyore.Iyi low-pressure steam system yakagadzirwa nemapombi akakurisa uye mavharuvhu ayo anogona kupa mamiriro ekushanda akanakisa.

TANODIKIDZIRWA KUBVA DAMPER

Kugadziriswa kwesimba remagetsi kunokosha zvikuru.Pasi pepamusoro pesimba remhepo, nguva yekugadzira ichawedzerwa uye ichipedza simba rakawanda.Zvakadaro, chigadzirwa chekupedzisira chinogona kuremara uye chitarisiko chepamusoro chechigadzirwa chinogona kukanganiswa kana kudzvanywa kwanyanya kuderera.Iyo yekununura damper inoshanda pakuburitsa mold uye kupisa mold.Iyo mhepo yakamanikidzwa inoshandiswa pakuzadza uye iyi damper inoderedza kushandiswa kwesimba uye inopa yakakwira mhando chigadzirwa.

THE HOLDING-PRESURE WATER TANK

Muchina uyu wakashongedzerwa neimwe seti yekubata pressure water hank ine maviri akasiyana ekupinda ekutonhodza mvura uye condensate.

VACUUM SYSTEM

Iyo vacuum system yakashongedzerwa neLiquid Ring Vacuum pombi uye condenser iyo inopa yakawedzera kushanda vacuity.Pasina imwe nhanho yekuomesa, tinogona kukurumidzira jekiseni pasi peiyi vacuum system.Iyo mold ejection iri nyore kupedzwa uye zvakare chengetedza iro rakawanda simba.

COMPUTER CONTROLLED SYSTEM

Muchina uyu wejekiseni wakashongedzerwa nekombuta-inodzorwa system ine mabasa epepeta uye kuwedzera.nhanho imwe neimwe yekushanda inonyatso pasi pekutonga nekombiyuta iyi yekuona kukanganisa kukanganisa uye zviratidzo zvinoratidzwa pachiratidziro Yese modhi inoiswa neiyi compute system iyo inoratidza maitiro, nguva yekumisikidza uye zvinonyanya kukosha kumanikidza control valve ichaisa kudzvanywa.

Mashoko

Tinogona kugadzira muchina zvinoenderana nezvinodiwa nemutengi.

EPS Machine:

EPS Machine Mufekitari Yevatengi

Application